PUMP SERVICES

Pump Repair & Services

We Perform Multiple types of services & Repair

on all types of Pumps. We use industry leading specs to maximize efficiency & longevity. When applicable, all rotating assemblies are fully balanced, all wear rings are repaired to proper efficiency tolerances, housings checked for damage, & mating surfaces are cleaned of faced to ensure a good seal.

Submersible Pumps

Multi-Stage Pumps

Centrifugal Pumps

Turbine Pumps

Split-Case Pumps

High Pressure Pumps

We offer repair & replacement options across all brands, as well as installation/start-ups, ceramic coatings for harsh applications, & custom machine work for obsolete parts when needed.

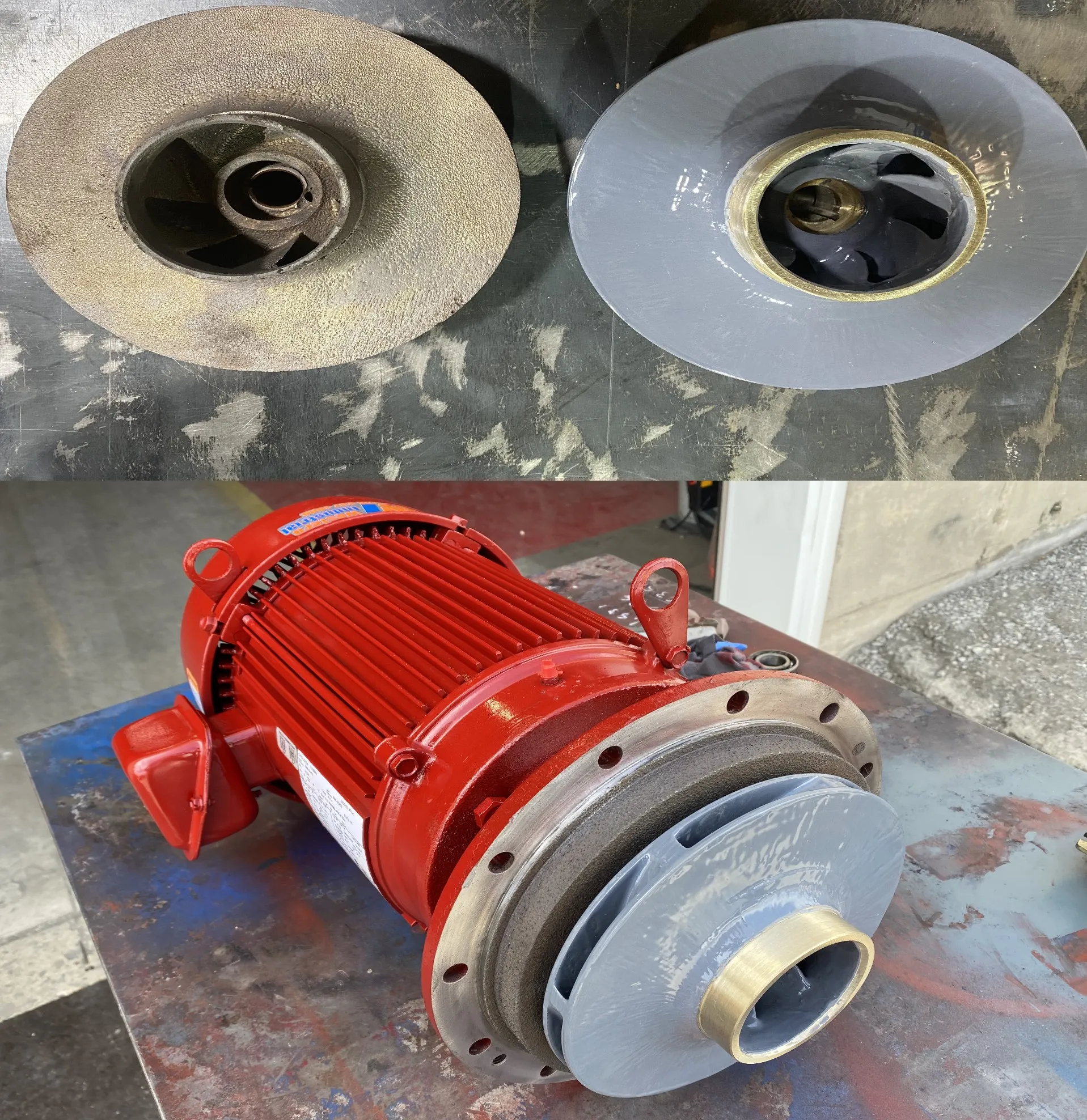

Recondition / Rebuild

Full dismantle, inspection, and tolerance checks. All pump components are verified to be within the specs outlined by EASA, or repaired to those specs. This includes impeller wear rings, seal seats, shaft seals, shaft sleeves, and volute wear rings. Then the pump is reassembled with new bearings, hardware, seals, and gaskets. All existing parts are fully cleaned/ blasted/ polished and painted during a recondition as well.

Machine Work

Pump efficiency relies on a few different factors. When a once good running pump starts to perform poorly, it doesn’t mean it isn’t able to be saved. Our capable machine shop can make, redesign, or rebuild multiple pump components to get them back to full efficiency. Whether it be a worn impeller wear ring, volute wear ring, shaft seal fit, or seal seat, it can be repaired back to required specs.

Submersible Pump Motors

Rewind, Recondition, and Repair services for all types and sizes of submersible pump motors. Finished sub pumps are coated in a 2 part submersible specific epoxy paint.

Impeller Coatings

We offer multiple options for reducing the wear and tear from impellers that run in chemicals, abrasive environments, or dirty environments. There are many coating options, including food grade, that can be applied to brand new impellers before they go into service, or used impellers that are still within operating specs.